01

THE SOLUTION

Embracing both the Green and Digital transitions means reimagining companies’ approaches to their end-to-end supply chains.

SEA Vision’s Digital Product Passport end-to-end traceability solution is the solution for cosmetic industry that safeguards the authenticity of cosmetics, ensuring transparency, quality, and customer engagement while actively combating global counterfeiting.

02

DIGITAL PRODUCT PASSPORT.

The way to connect your company to your customers.

Digital Product Passports (DPPs) can promote circularity in the industry by providing transparency regarding raw material sourcing, integrating circular design principles, and tracking waste management. This solution allows brands to showcase their commitment to sustainability, moving beyond mere marketing strategies by delivering verifiable and transparent information directly to consumers in an immutable format.

With DPPs, new possibilities emerge for both upstream and downstream activities:

Upstream: Securely store and transparently share product details throughout the entire value chain, highlighting sustainability and circular practices (such as ethical sourcing, craftsmanship, material extraction, and recycling), whether voluntarily or to meet regulatory requirements.

Downstream: Establish a new platform for direct engagement with individual customers, both pre- and post-sale, across all purchasing channels, (e.g., brand-owned stores and wholesale distributors.

For companies, the Digital Product Passport (DPP) presents opportunities to streamline supply chains, combat grey market activity, minimize environmental impact, and strengthen brand image. It allows businesses to meet the rising expectations of eco-conscious consumers and comply with regulatory standards.

With easy access to a product’s sustainability credentials, consumers can choose brands that align with their values, promoting a culture of responsible consumption.

03

TECHNICAL SOLUTION IN DETAIL

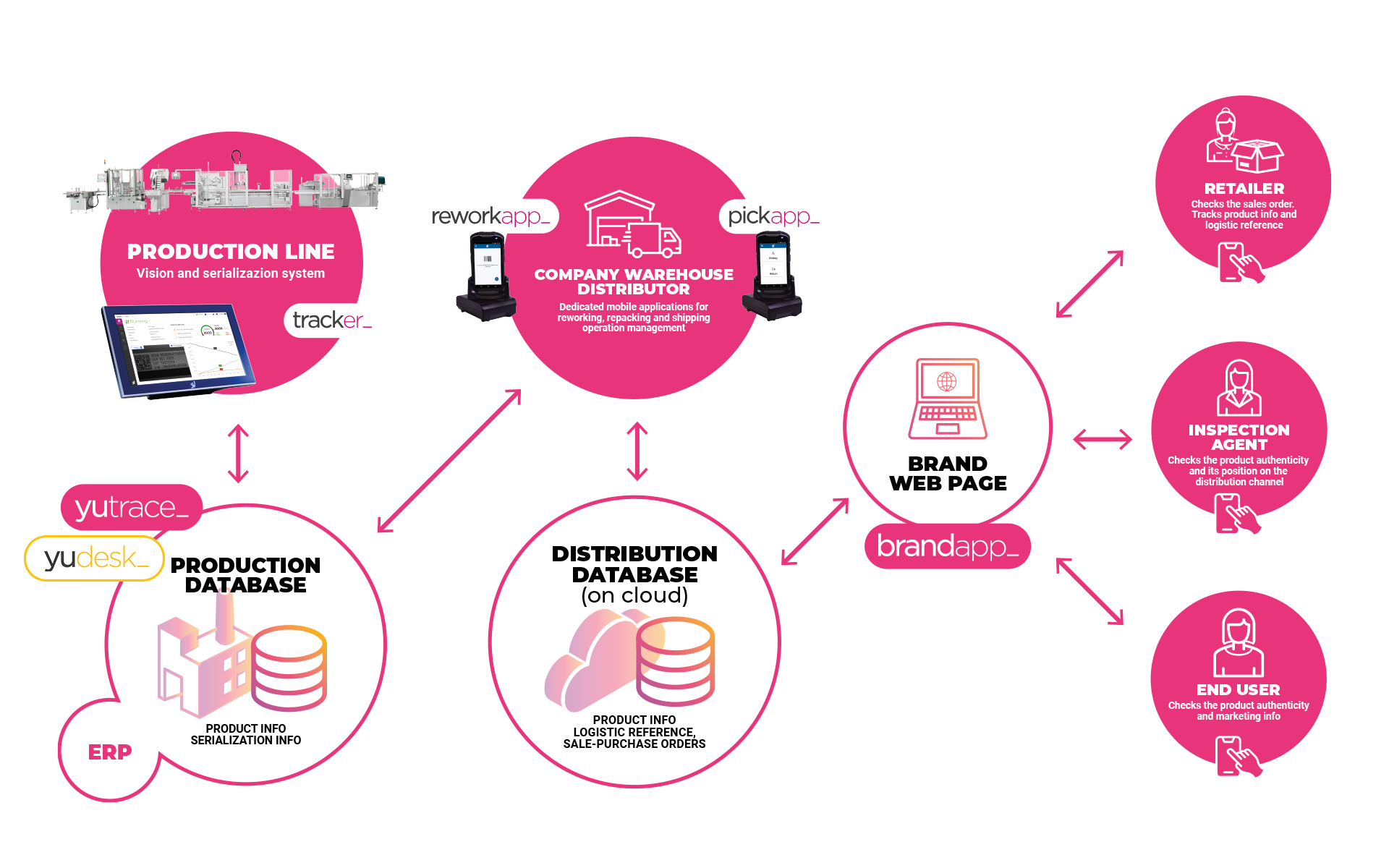

This is a typical scenario that enable the end-to-end traceability solution. Our solution leverages on SEA Vision’s 20 years of experience in track and trace. Let’s discover in detail every solution component.

YUTRACE

yutrace is the traceability solution for the production site, is used to gather and store production and traceability data into the production database. Yutrace autogenerates the unique identifier and communicates with the line systems.

YUDESK

Yudesk is the configuration module of yudoo software suite, allows you to include all the information related to your product and link it with the unique identifier

TRACKER

It is the vision and traceability system used on the machines of the packaging line to manage the printing and check the cosmetic unique identifier.

Tracker is a camera-based system performing control, serialization and aggregation operations. It is installed on one or more packaging machines, exchanging with them real time information through digital signals.

REWORKAPP

It is a warehouse rework mobile application used to perform reworking operations, whose results are transferred into the production database.

Reworkapp allows the operator to reach any part of the warehouse and rework the products where they are. The main features of reworkapp for warehouse operations are: Disaggregation, Rejection, Sampling.

PICKAPP

It is a warehouse picking mobile application used for order fulfillment management. The data recovered from the production database are enriched with logistical data and are then archived in a dedicated distribution database.

The great advantage of this application consists in the digitalization of a workflow that is usually paper-based. This increases the speed and the efficiency of the process.

DATABASES

Production and Distribution databases includes all your production and traceability information and allows you to trace your products along the supply chain. The production database can’t be accessed from outside of your company for ensuring maximum safety. Your business partner such as 3PL, Distributor or agent can add additional data related to the different sales channels in your chain. All the data can be easily retrieved for KPI analysis.

WEBSITE

On a dedicated product web page we connect the physical product with the digital information inside the database. Our system can be tailored with specialized functionalities for distinct user roles (Brand owner, company agent, retailer, end-user), all focused on verifying post-marketing product authenticity. Customer experience can be tailor made to deliver dedicated messages related to safety, formulation and brand identity.

DOWNLOAD THE CATALOGUE>>>